Not only a modern interface and extreme ease of use: the IC software is a concentrate of technology and experience, as explained by Filippo Bostrenghi, Intermac software director.

Over 7,000 packages installed in 180 Countries: iCam is the most widely used CAD/CAM software in the world for applications relating to glass, and the numbers prove it. Experience and reliability are the keys to the software's popularity and have driven Intermac to create a software package that's even better, IC. As is suggested by the play on words (I see) the software has taken a leap forward, from the interface, which is now even easier to learn and more intuitive, to the optimal use of processing power, to achieve no-compromise functionality and flexibility when programming. We asked Filippo Bostrenghi, head of software development for Intermac, to take us on a behind-the-scenes tour of IC.

Where did you start with IC?

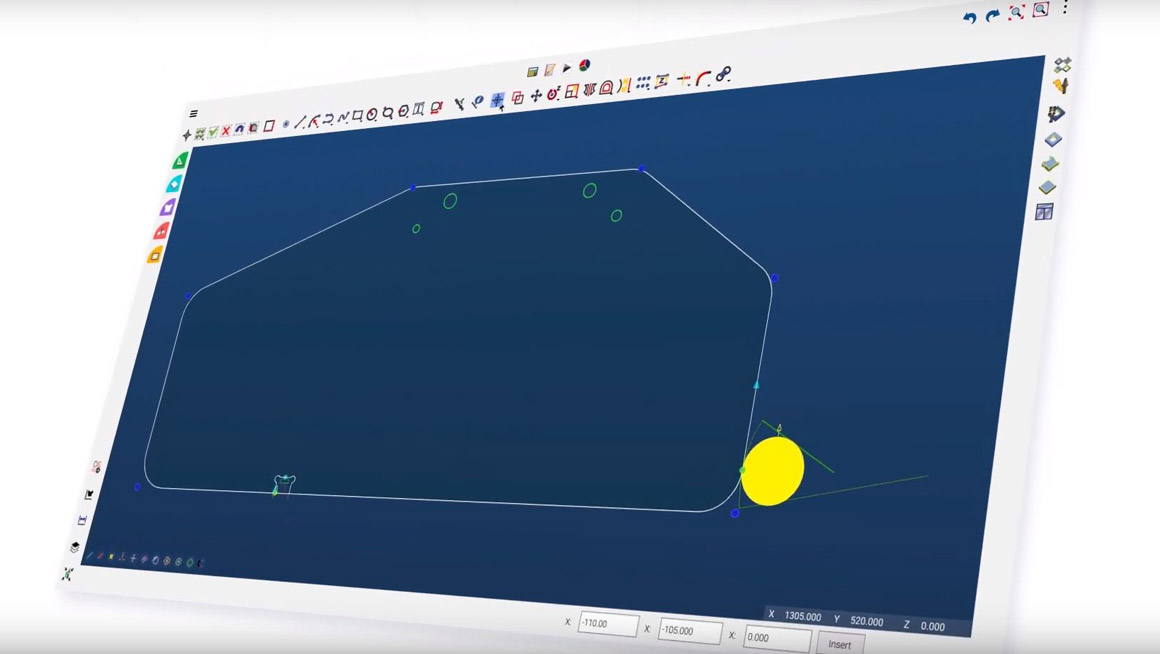

"The starting point was itself an innovation since we kept development focused on ease of use. Machine software is often developed by engineers “for engineers”. The result is applications that are very rich in terms of functionality, but with an approach and a modus operandi that loses sight of the people who will actually use the software. The learning curve is therefore very steep. Our new approach to development had already made life easier for users with B_SOLID. But to reach the level of simplicity achieved by IC - i.e. just 5 buttons for the work done on a daily basis - development had to be even more research-based. Thanks to our direct experience with customers, we systematically studied how operators use the software and figured out which actions are the most frequent. We then focused on the steps that are executed most often for everyday operations, such as importing files, taking measurements on the field, or machining models that need to be parameterised. By standing shoulder to shoulder with customers who use iCam and B_SOLID on a daily basis, we collected several thousand cases of use over time. The experience helped us detect characteristic patterns of use: i.e. whether designs are created from a series of measurements or the user already has a completed model that needs to converted to machine language. That's how we were able to achieve the current level of simplicity, responding to our customers' actual needs and priorities. While ease of use was the objective, we also needed to satisfy more demanding customers who have extensive programming experience. These two apparently contradictory needs highlight the strength of IC, which incorporates iCAM but also offers a simplified interface. For the main operations, which account for 80% of cases, 5 buttons are all the operator needs, while for the remaining 20%, where advanced programming is needed, the user simply clicks a button to access an advanced version of the software with all the functions necessary for the most complex projects. Rather than merely restyling, we took up the challenge of simplifying the most frequent functions and did away with complex steps that end up being useless for most everyday operations".

_anteprima.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

中國

中國

Asia

Asia

Deutschland

Deutschland

España

España

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand