We simplify your manufacturing process to make the potential of any material shine.

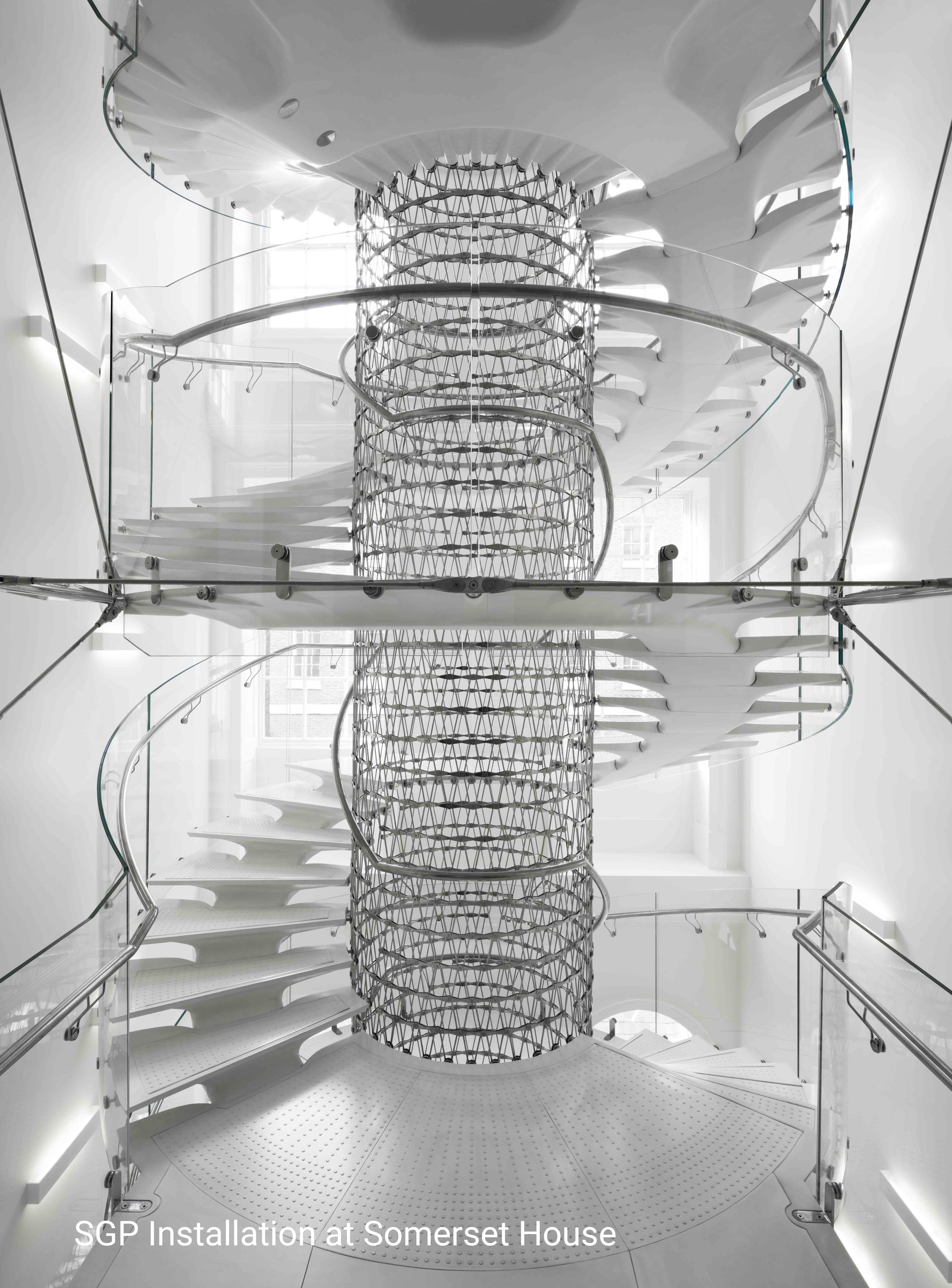

Specialist Glass Products Increases productivity by 137% thanks to Intermac’s high-tech glass processing machines

137% Increased Productivity

SGP are a specialist glass manufacturer that has earned a longstanding reputation for exceeding expectations. Based in Yorkshire, they have supplied flat, curved, annealed, toughened, laminated and double glazed glass solutions for over 11 years and use Intermac glass processing machines to help improve productivity and efficiency.

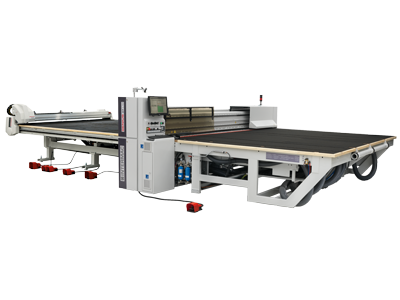

“We were limited by what we could process”, commented Andrew, “the largest sheet we could handle was 3.2m x 2.5m, so we invested in a brand new facility with a new Intermac Genius cutting line with a Movetro automatic glass loading storage and retrieval system and a Vertmax vertical CNC machining centre. We can now process, cut, toughen and laminate glass up to 6000mm x 3210mm.”

The Vertmax has had a massive impact on SGP’s productivity. Their average output to process a panel on their horizontal Intermac Master 33 CNC was 2 per hour. This has now improved to at least 4 per hour with the Vertmax due to increased processing speeds and virtually zero set-up time.

They can also load another panel on the conveyor whilst one is being processed, thus increasing efficiency further. “When each piece is a different size, the machine comes into its own,” added Andrew. “It’s also opened up new markets for us. In addition to being able to process jumbo sheets, we can now edge delete soft coated glass prior to toughening or bending, which is something we couldn’t do before.”

Regarding the Genius cutting line and Movetro loading and storage system Jonathan commented, “Our existing cutting line was automatic, but only had 6 loading stations, which meant due to the large number of different products we process, a lot still had to be loaded manually. The new system with 44 stations that can hold up to 88 different products has been a massive improvement. It’s like going from a hot air balloon to Concorde overnight! It has virtually eliminated the need for time consuming manual loading.”

“We’ve now gone from cutting sheets 8m² to 19m², in almost the same length of time. It’s a massive increase in productivity as we’ve managed to double our potential cutting output. Again, it’s opened up new markets for us, not only due to cutting larger panels but the machine also has an edge deletion facility so we can now process soft coated glass.”

“Our relationship with Intermac, with their consultative approach and inherent quality of machines, has been instrumental in our success as a specialist glass supplier.”

“And yes, the investment was worth it! We now have complete control over everything we do, with new markets and greater efficiencies,” concluded Andrew.

An impressive factory with what looks like a very bright future

In general, processing jumbo sheets with the Genius, Movetro and Vertmax has increased the overall optimisation of sheets which has resulted in a 10% reduction in waste material, which is a significant saving.

_anteprima.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

中國

中國

Asia

Asia

Deutschland

Deutschland

España

España

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand