The types of architectural glass projects FA Firman gets involved with can be summarised as challenging, unconventional and cutting edge. This is a company that has attained almost legendary status in architect and structural engineering circles, owing to its ability to push boundaries in glass working.

“If it is anything big, heavy, structural or complex, it tends to end up with us. It is fair to say that we have a reputation among architects for being able to deliver the demanding projects that other glass processors don’t know how to tackle,” says managing director Jody Hodgson, whose father John Hodgson founded the Romford-based company in 1975.

High-profile projects

This ‘no limits’ approach has seen FA Firman work on some of the most prestigious projects in the world of glass. A 12-metre high glass wall for the Royal Opera House in Covent Garden and a glass pergola for Pembroke College, Cambridge, are just two of the notable schemes the company has undertaken.

However, FA Firman’s most defining moment was the creation of a canopy for the Yurakucho underground station in Tokyo back in the 1990s. The longest cantilevered all-glass structure ever built, this project defied the boundaries of glass technology and won Firmans a special commendation for expertise in the 1997 British Construction Awards.

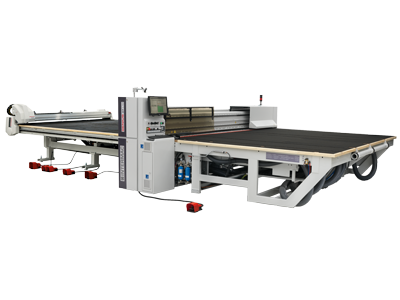

The glass sheets for the canopy were machined on FA Firman’s first Intermac CNC, a Master 2000, and Firmans freely admits that without being an early adopter of this technology, it would never have been able to take on the pivotal Tokyo project, or the ones that followed on the back of this success.

“That project catapulted us from relative obscurity to prominence in the architectural engineering community and led to all sorts of weird and wonderful projects, where Intermac technology became a must,” says Jody.

Strength in CNC

The Intermac advantage comes into play when producing toughened laminates from two glass panels. This requires two perfectly sized pieces of glass that fit together seamlessly to avoid a stepped edge.

“When we laminate two pieces of glass, the Intermac gives perfect edge alignment, which has earned us a reputation for accuracy and the ability to machine bespoke pieces of glass to very tight tolerances,” says Jody.

As well as marking the start of a lifelong partnership between the two companies, that first Intermac investment served as a springboard for growth and continuous investment, as Jody explains:

“Over the last 30 years we have gone from strength to strength, thanks to our partnership with Biesse. Our investment in that first machine generated enough business to invest £500,000 in a toughening plant. We are now on our third toughening plant, and our newest has a bed size of 5x3m, which is large by UK standards.”

_anteprima.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

中國

中國

Asia

Asia

Deutschland

Deutschland

España

España

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

- Copy.jpg)