Semplifichiamo i processi produttivi per esaltare il potenziale di ogni materiale.

Reaching new levels of artistry and productivity

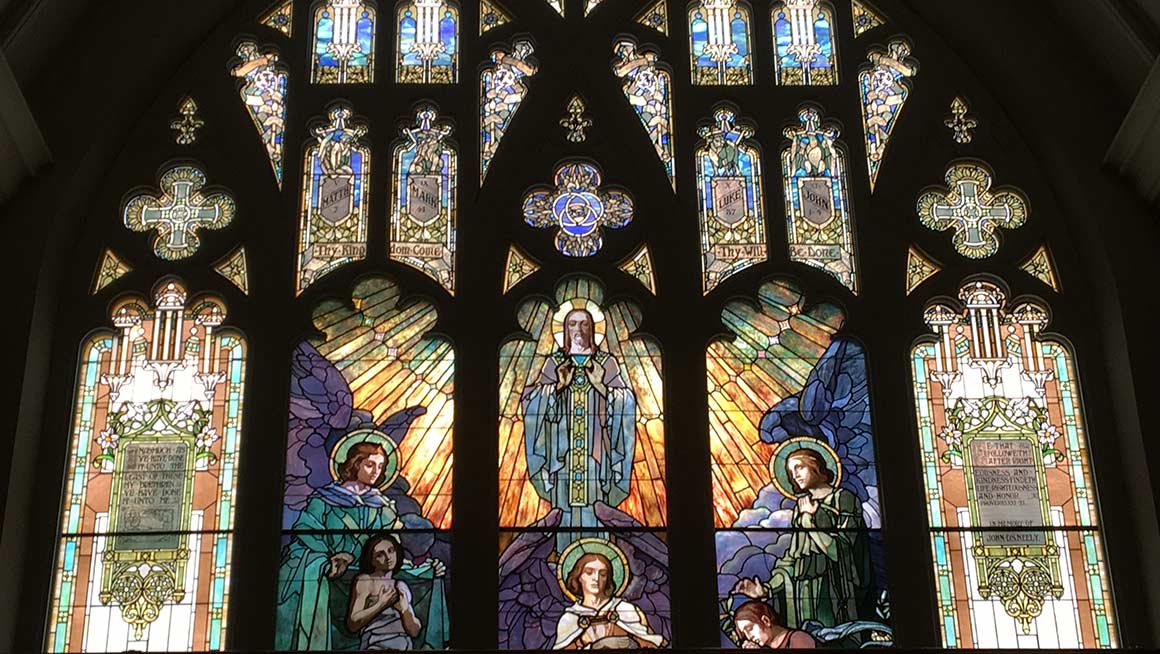

“Our primary business is stained glass but we’re moving more and more to manufacturing,” said company president Reggie Buehrer. “Still, the manufacturing revolves around the window business but we’re branching off into other areas. Anything pertaining to glass, metal or wood, we can work with all those different mediums.” Buehrer noted that a large stained glass window might be composed of 50 or 60 panels and Window Creations produces “well into the thousands” of pieces each year when you combine those panels, window frames and wood projects.

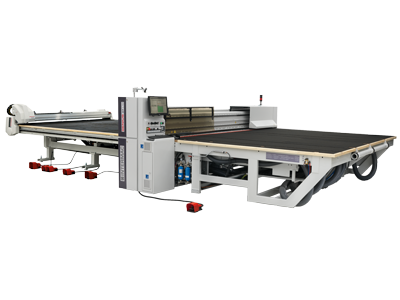

Two years ago, the company encountered some production challenges and found the help it was looking for in Intermac’s Genius CT-37 and Biesse’s Rover S. “We were looking to save time and improve accuracy,” he said. “With Intermac, we were primarily looking at glass cutting, mostly ¼-inch thick but all different thicknesses. We were looking for something that would improve accuracy versus hand cutting and using templates and then also to be able to speed the process up. That really did help increase the speed at which we were able to work and, of course, the accuracy.” Buehrer added, “It’s really about time savings, greater precision and less material loss. On the CT-37, with big projects we often times end up with 90%-plus usage of our sheet because we’re nesting so many pieces. It’s a pretty high percentage, let’s put it that way. We may have hundreds of panels we punch into it at a time, so it really figures the placement in the piece and it nests them really well.”

For its part, the Rover S has proved beneficial not only in the company’s production for customers but also for the enhancement of Window Creations’ own work environment. “We use it for milling wood, of course, but use it for three-dimensional type coves,” Buehrer said. “It’s a little more than just cutting out a two-dimensional piece. We use software that allows us to go in and put those coves on it and do some really cool things. We also made all the cabinets for our new facility. We engineered them on CAD software and it automatically sent the code to the (Rover). It chops them up, into literally thousands of pieces, and drills the holes for the shelves and dadoes out the holes. It was really nice for making the cabinets.” Window Creations, LLC, counts many churches and secular clients among its growing list of customers.

For its part, the Rover S has proved beneficial not only in the company’s production for customers but also for the enhancement of Window Creations’ own work environment. “We use it for milling wood, of course, but use it for three-dimensional type coves,” Buehrer said. “It’s a little more than just cutting out a two-dimensional piece. We use software that allows us to go in and put those coves on it and do some really cool things. “We also made all the cabinets for our new facility. We engineered them on CAD software and it automatically sent the code to the (Rover). It chops them up, into literally thousands of pieces, and drills the holes for the shelves and dadoes out the holes. It was really nice for making the cabinets.” Window Creations, LLC, counts many churches and secular clients among its growing list of customers.

With Intermac, we were primarily looking at glass cutting, mostly ¼-inch thick but all different thicknesses. We were looking for something that would improve accuracy versus hand cutting and using templates and then also to be able to speed the process up. That really did help increase the speed at which we were able to work and, of course, the accuracy.

_anteprima.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

France

France

中國

中國

Asia

Asia

Deutschland

Deutschland

España

España

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand